Supported Devices

Calamp

Device Summary

The Calamp device is a versatile hardware solution integrated with the GSatTrack platform, designed for advanced tracking and telematics. It supports a wide range of applications, from fleet management to asset tracking, providing users with real-time data and analytics to improve operational efficiency. The device is known for its robust performance, extensive I/O options, and compatibility with various sensors and peripherals, making it a powerful tool in both commercial and industrial environments.

Device Setup

Diagnostics

If your CalAmp device is equipped with status LEDs, please check their indicators. The green GPS LED and the orange Communications LED should both be solid. If the green LED is off or blinking, it means that a valid GPS position cannot be determined, and no positions will be updated on the portal. If the orange LED is off or blinking, it indicates a lack of data connectivity, preventing any communication with the portal.

- If the orange Communications LED is not solid, the first step is to verify that the cellular data settings are correct for the SIM card in use.

- If the green GPS LED is not solid, note that it may take several minutes for the device to acquire an initial GPS position and establish GPS time synchronization.

Setup

The Calamp devices are managed remotely via a central repository, but the devices must be programmed with the APN information before they can connect to the repository. To program a terminal that is new, or changing network operators, do the following:

Connect the Calamp via a serial port at 115200 bps, 8N1

Connect via terminal software such as Hyperterm, putty, or screen

Enter the following commands:

AT$APP DEBUG ON

AT$APP PARAM 768,0,66.165.183.84

AT$APP PARAM 769,0,4763

AT$APP GPRS CONTEXT 0 “{APN}”

AT$APP PARAM 2314,0,”{APN Username}”

AT$APP PARAM 2315,0,”{APN Password}”

AT$APP GPRS CONTEXT 1 “{APN}”

AT$APP PARAM 2314,1,”{APN Username}”

AT$APP PARAM 2315,1,”{APN Password}”

AT$APP PARAM 1024,35,255,1

AT$APP PEG ACTION 70 0

The unit will now reboot. Once the terminal is restarted, enter the following command to force an immediate connection:

- AT$APP PEG ACTION 49 129

The unit will now download the script from the central repository and begin reporting. This can take up to 30 minutes in poor network coverage.

SMS Setup

The APN information can also be configured via SMS if a serial connection is not an option or it needs to be changed remotely:

APN:

- !RP,2306,0,{APN}

APN Username:

- !RP,2314,0,{APN Username}

APN Password:

- !RP,2315,0,{APN Password}

Server IP Address for:

- (32 bit LMU) !RP,768,0,66.165.183.84

- (8 bit LMU) !RP,2319,0,66.165.183.84

- (8 bit LMU) !RP,2319,1,66.165.183.84

Server UDP Port:

- !RP,769,0,4763

Reset Device:

- !R3,70,0

Send Maintenance Report (to download configuration updates):

- !R3,49,129

Upgrading Firmware

Use a serial terminal program such as HyperTerm with the YModem protocol

If you do not have HyperTerminal you can use a free utility here: http://en.sourceforge.jp/projects/ttssh2/releases/

- Open the terminal program (HyperTerm) and connect to the serial port at 115200 8N1

- Enter “ATDNLD” and the unit will be ready for the file transfer

- Using the YModem protocol, send the firmware binary to the unit

Firmware: LMU-GSM-170-30g.bin` LMU-26xx and LMU-27xx GSM ONLY

Firmware: LMU-HSPA-176-33b.bin LMU-4x5x Iridium and GSM

Updating Configuration Locally

Download this AppendCRC16toBin.exe program to convert scripts to directly loadable files.

- If you do not have HyperTerminal you can use a free utility here: http://en.sourceforge.jp/projects/ttssh2/releases/

Start here to export your script from LMU Manager. If you already have a script ready, skip to “Loading the script” below.

- Export the script from LMU manager to a CSV

- Open Command prompt and enter ‘AppendCRC16toBin.exe’ and then the name of the script file you want to convert

- Once this has finished it will have overwritten the existing script file and added characters at the end of the parameter list.

Loading the script

Using HyperTerm

- Open the terminal program (HyperTerm) and connect to the serial port at 115200 8N1

- Enter “ATDSCFG” and the unit will be ready for the file transfer

- Using the YModem protocol, send the configuration file (.csv) to the unit

- Press ‘Send’ button. You should see a list of the records being written.

Using Tera Term

- Open the terminal program (Tera Term) and connect to the serial port at 115200 8N1

- Enter “ATDSCFG” and the unit will be ready for the file transfer

- Go to File -> Transfer -> YMODEM -> Send and select the configuration file (.csv) to send to the unit

- Press ‘OK’. You should see a list of the records being written.

RSSI

Signal Strength Equivalents

| Signal Level | Bars | RSSI Range |

|---|---|---|

| Great | 5 | >= -77 |

| Good | 4 | >= -78 < -86 |

| Average | 3 | >= -87 < -92 |

| Poor | 2 | >= -93 < -101 |

| Bad | 1 | < -102 |

LMU-26x0/LMU-27x0

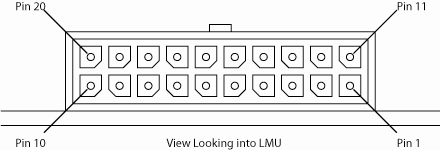

Pinout

PDF: 5C908 Datasheet

| Pin | Signal Name | Description | 5C908 Color | Input or Output |

|---|---|---|---|---|

| 1 | GND | Ground | Black | Ground |

| 2 | OUT-1 | Output 1 – Starter Disable Relay Driver | Green | Output |

| 3 | IN-1 | Input 1 – Digital Input | Blue | Input |

| 4 | SER_IN | Serial Input | Blue | Input |

| 5 | ADC-1 | Analog to Digital Input 1 | Pink | Input |

| 6 | IN-3 | Input 3 – Digital Input | Violet | Input |

| 7 | IN-4 | Input 4 – Digital Input | Grey | Input |

| 8 | IN-0 | Ignition | White | Input |

| 9 | VDD | VDD Reference Output (20-25mA Max) | Orange | Output |

| 10 | OUT-2/BOOT | Output 2 – Digital Output (Open Collector) BOOT Input | Brown | Input / Output |

| 11 | OUT-3 | Output – 3 Digital Output (Open Collector) | Yellow | Output |

| 12 | IN-2 | Input 2 – Digital Input | Orange | Input |

| 13 | SER_OUT | Serial Output | Green | Output |

| 14 | VCC | Primary Power Input | Red | Power |

| 15 | GND | Primary Ground | Black | Ground |

| 16 | 1BB-GND | 1 Bit Bus Ground | Black | Ground |

| 17 | 1BB-D | 1-Bit Bus Data | White/Blue | Input / Output |

| 18 | Aux - TxD | Aux Port 2 - Transmit Data | White/Orange | Input |

| 19 | Aux - GND | Aux Port 2 - Ground | Black | Ground |

| 20 | Aux - RxD | Aux Port 2 - Receive Data | White/Yellow | Output |

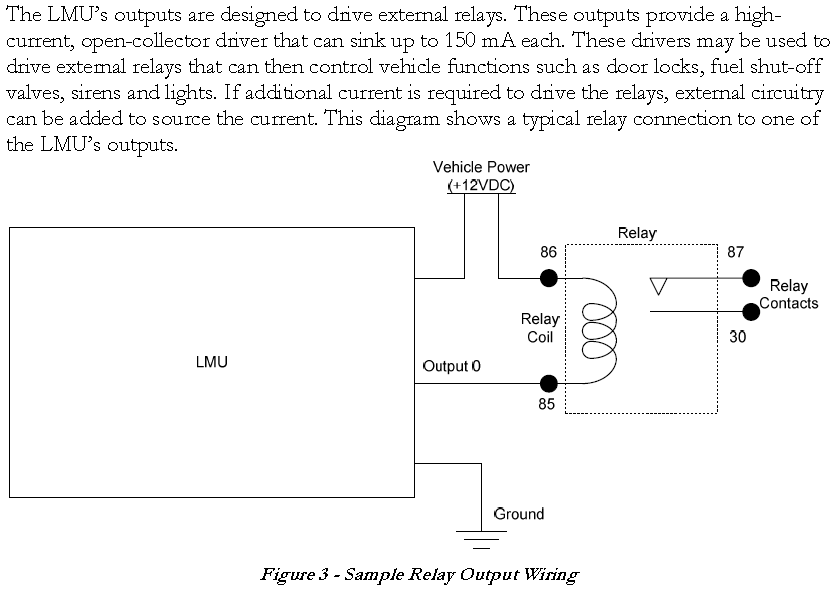

Relay Wiring

The LMU’s outputs are designed to drive external relays. These outputs provide a high current, open-collector driver that can sink up to 150 mA each. These drivers may be used to drive external relays that can then control vehicle functions such as door locks, fuel shut-off valves, sirens, and lights. If additional current is required to drive the relays, external circuitry can be added to source the current. This diagram shows a typical relay connection to one of the LMU’s outputs.

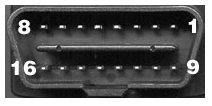

LMU-3000

Configuration

- Connect pin 16 to battery +

- Connect pin 4 to ground

- Connect serial port interface

- Follow “Setup” instructions above to program the APN

Pinout

| Pin | Signal Name | Description | Color | Input or Output |

|---|---|---|---|---|

| 1 | VIN | Primary Power | Red | Power |

| 2 | GND | Ground | Black | Ground |

| 3 | INPUT 0 | Input 0 - Ignition | White | Input |

| 4 | ADC1 | Analog to Digital Input 1 | Pink | Input |

| 5 | VIN_FILT | Brown/Red | ||

| 6 | AUX1_VCC | Aux Port 1 - Power | Brown/Orange | Power |

| 7 | GND | Ground | Black | Ground |

| 8 | AUX1_RX | Aux Port 1 - Receive Data | Brown/Green | Input |

| 9 | AUX1_TX | Aux Port 1 - Transmit Data | Brown/Blue | Receive |

| 10 | VIN_FILT | Yellow/Red | ||

| 11 | AUX2_VCC | Aux Port 2 - Power | Yellow/Orange | Power |

| 12 | AUX2_RX | Aux Port 2 - Receive Data | Yellow/Green | Input |

| 13 | AUX2_TX | Aux Port 2 - Transmit Data | Yellow/Blue | Output |

| 14 | INPUT 1 | Input 1 - Digital Input | Blue | Input |

| 15 | INPUT 2 | Input 2 - Digital Input | Orange | Input |

| 16 | INPUT 3 | Input 3 - Digital Input | Violet | Input |

| 17 | INPUT 4 | Input 4 - Digital Input | Gray | Input |

| 18 | INPUT 5 | Input 5 - Digital Input | Green/White | Input |

| 19 | INPUT 6 | Input 6 - Digital Input | Blue/White | Input |

| 20 | INPUT 7 | Input 7 - Digital Input | Black/White | Input |

| 21 | 1BB_T_DATA | 1-Bit Bus Transmit Data | Green/Black | Output |

| 22 | 1BB_GND | 1-Bit Bus Ground | Black | Ground |

| 23 | 1BB_R_DATA | 1-Bit Bus Receive Data | Orange/Black | Input |

| 24 | OUTPUT 0 | Output 0 - Digital Output | Green | Output |

| 25 | OUTPUT 1 | Output 1 - Digital Output | Brown | Output |

| 26 | OUTPUT 2 | Output 2 - Digital Output | Yellow | Output |

| 27 | OUTPUT 3 | Output 3 - Digital Output | Blue/Orange | Output |

| 28 | OUTPUT 4 | Output 4 - Digital Output | White/Yellow | Output |

| 29 | LED OUTPUT 1 | Output 5 - LED Driver | Red/Green | Output |

| 30 | LED OUTPUT 2 | Output 6 - LED Driver | Orange/Green | Output |

| 31 | ADC2 INPUT | Analog to Digital Input 2 | Black/Red | Input |

| 32 | ADC3 INPUT | Analog to Digital Input 3 | White/Red | Input |

| 33 | ADC4 INPUT | Analog to Digital Input 4 | Orange/Red | Input |

| 34 | ADC5 INPUT | Analog to Digital Input 5 | Blue/Red | Input |

LMU-4250

Pinout

| Pin | Signal Name | Description | Color | Input or Output |

|---|---|---|---|---|

| 1 | VIN | Primary Power | Red | Power |

| 2 | GND | Ground | Black | Ground |

| 3 | INPUT 0 | Input 0 - Ignition | White | Input |

| 4 | ADC1 | Analog to Digital Input 1 | Pink | Input |

| 5 | VIN_FILT | Brown/Red | ||

| 6 | AUX1_VCC | Aux Port 1 - Power | Brown/Orange | Power |

| 7 | GND | Ground | Black | Ground |

| 8 | AUX1_RX | Aux Port 1 - Receive Data | Brown/Green | Input |

| 9 | AUX1_TX | Aux Port 1 - Transmit Data | Brown/Blue | Receive |

| 10 | VIN_FILT | Yellow/Red | ||

| 11 | AUX2_VCC | Aux Port 2 - Power | Yellow/Orange | Power |

| 12 | AUX2_RX | Aux Port 2 - Receive Data | Yellow/Green | Input |

| 13 | AUX2_TX | Aux Port 2 - Transmit Data | Yellow/Blue | Output |

| 14 | INPUT 1 | Input 1 - Digital Input | Blue | Input |

| 15 | INPUT 2 | Input 2 - Digital Input | Orange | Input |

| 16 | INPUT 3 | Input 3 - Digital Input | Violet | Input |

| 17 | INPUT 4 | Input 4 - Digital Input | Gray | Input |

| 18 | INPUT 5 | Input 5 - Digital Input | Green/White | Input |

| 19 | INPUT 6 | Input 6 - Digital Input | Blue/White | Input |

| 20 | INPUT 7 | Input 7 - Digital Input | Black/White | Input |

| 21 | 1BB_T_DATA | 1-Bit Bus Transmit Data | Green/Black | Output |

| 22 | 1BB_GND | 1-Bit Bus Ground | Black | Ground |

| 23 | 1BB_R_DATA | 1-Bit Bus Receive Data | Orange/Black | Input |

| 24 | OUTPUT 0 | Output 0 - Digital Output | Green | Output |

| 25 | OUTPUT 1 | Output 1 - Digital Output | Brown | Output |

| 26 | OUTPUT 2 | Output 2 - Digital Output | Yellow | Output |

| 27 | OUTPUT 3 | Output 3 - Digital Output | Blue/Orange | Output |

| 28 | OUTPUT 4 | Output 4 - Digital Output | White/Yellow | Output |

| 29 | LED OUTPUT 1 | Output 5 - LED Driver | Red/Green | Output |

| 30 | LED OUTPUT 2 | Output 6 - LED Driver | Orange/Green | Output |

| 31 | ADC2 INPUT | Analog to Digital Input 2 | Black/Red | Input |

| 32 | ADC3 INPUT | Analog to Digital Input 3 | White/Red | Input |

| 33 | ADC4 INPUT | Analog to Digital Input 4 | Orange/Red | Input |

| 34 | ADC5 INPUT | Analog to Digital Input 5 | Blue/Red | Input |

I/O Descriptions

Digital Inputs

Input 0: Ignition Sense (Always biased low)

- Input 1: Generic Digital Input (Biased high or low/ S-158 Bit 1)

- Input 2: Generic Digital Input (Biased high or low/ S-158 Bit 2)

- Input 3: Generic Digital Input (Biased high or low/ S-158 Bit 3)

- Input 4: Generic Digital Input (Biased high or low/ S-158 Bit 4)

- Input 5: Generic Digital Input (Biased high or low/ S-158 Bit 5)

- Input 6: Generic Digital Input (Biased high or low/ S-158 Bit 6)

- Input 7: Generic Digital Input (Biased high or low/ S-158 Bit 7)

- Input 8: Motion Sensor

- Input 9: VBUS Active

- Input 10: Power State

- Input 11: Vbatt Low

Analog to Digital Inputs

- A/D 0: External Power Supply Monitor

- A/D 1: Generic External Analog to Digital Input

- A/D 2: Generic External Analog to Digital Input

- A/D 3: Generic External Analog to Digital Input

- A/D 4: Generic External Analog to Digital Input

- A/D 5: Generic External Analog to Digital Input

- A/D 6: GPS Antenna Monitor

- A/D 7: GPS Antenna Monitor

- A/D 8: Internal Temp Monitor

- A/D 9: Vref

- A/D 10: Battery Voltage

Outputs:

- Output 0: Standard Open Collector Relay Output

- Output 1: Standard Open Collector Relay Output

- Output 2: Standard Open Collector Relay Output

- Output 3: Standard Open Collector Relay Output

- Output 4: Standard Open Collector Relay Output

- Output 5: Standard LED Driver

- Output 6: Standard LED Driver

- Output 7: Power Switch

- Output 8: Charge Disable

iButton / 1 Bit Bus

- iButton ID Support

- 1-Wire bus with current boost for temperature sensors

Sensors and Accumulators

The platform is by default set to accept temperature in accumulator 0 and fuel level in accumulator 1.

The temperature is received in Celsius and is multiplied by 16.

The fuel level which is translated to a voltage is multiplied by 1000. IE 4800 translates to 4.8V

Fuel

The Calamp series can be connected to a VDO device which translates the fuel level with a tank profile into a sliding scale voltage of 0 to 10 volts which represents a fuel level of empty to full.

TheUltrasonic-Fuel-Sensor-UL-200 is also supported.

1-Wire Sensors

The Calamp series supports 1-wire temperature sensors. Temperature sensors based on the DS18B20 support a single sensor, and the DS28EA00 supports up to 8 sensors in a chain.

https://www.sparkfun.com/products/11050

Single temperature sensor model 1WT_6SSP_1_5m_2w

Red: Connect to Calamp GND - Black wire

White: Connect to Calamp 1 Wire Data - White/Blue Stripe

Up to 8 temperature sensors daisy-chained: Datanab

Temperature plus Humidity sensor (HTS Sensor)

https://www.adafruit.com/product/393

- Sample configuration for LMU27xx 27xx-sample-calamp-humidity.csv

- Firmware version MUST be 3.7b or higher

- Bit 0 of S register 171 must be cleared (IE: 0)

- Bit 4 of S register 181 must be set (IE: 16)

- Wire HTS Sensor Red to 5V (Pin 9: Orange)

- Wire HTS Sensor White/Black to GND or 1BB GND (Pin 1 or 16: Black)

- Wire HTS Sensor Yellow to 1BB Data (Pin 17: White/Blue)

LMU-2xx0

To connect a single temperature sensor, connect the DATA pin of the temperature sensor which is typically white on a 4-wire model and red on a 2-wire model to the White/Blue wire on the Calamp. Then connect the GND wire which is typically black to any ground/black wire of the Calamp.

Notes

- To enable the 1-wire bus the S register 171 must be set to 65. Ex: “ATS171=65”

- To push the temperature sensor data to the accumulator, the PEG Action Move Temp Sensors to Accumulator (93) can be used. Ex: “AT$APP PEG ACTION 93 0” sets temperature sensor 0 to push its value to accumulator 0

- To transmit the accumulator over the air, the Accumulator Number (772, 773) must be set to the number of accumulators to transmit under Report Contents > Event Report Optional Contents > Accumulator Number in LMU Manager: Ex: 1

Position Size

Standard position reports are 54 bytes + UDP header (minimum of 28 bytes) = 82 bytes minimum depending on TCP header size

Additional Information

Key Features

- Real-Time Tracking: Provides accurate and up-to-date location data for assets, enabling better management and visibility.

- Extensive I/O Capabilities: Supports multiple I/O connections, allowing integration with various sensors and devices for enhanced monitoring.

- Geofencing: Offers geofencing capabilities to define virtual boundaries and receive alerts when assets enter or exit designated areas.

- Event-Based Reporting: Configurable to report specific events such as movement, stops, or engine status, ensuring timely and relevant data.

- Remote Configuration: Allows for over-the-air updates and configuration changes, reducing the need for on-site maintenance.

- Rugged Design: Built to withstand harsh environments, making it suitable for use in challenging conditions.

Use Cases

- Fleet Management: Track and monitor vehicle locations, routes, and statuses in real-time to optimize fleet operations.

- Asset Tracking: Keep tabs on valuable assets in transit, ensuring they are secure and arriving at their destinations as planned.

- Environmental Monitoring: Integrate with temperature, humidity, and other environmental sensors to monitor conditions during transportation.

- Geofencing Alerts: Receive notifications when assets enter or leave specific areas, improving security and operational control.

- Preventive Maintenance: Use data from the device to schedule maintenance activities based on actual usage, reducing downtime.

- Fuel Management: Monitor fuel consumption and detect any discrepancies or theft, helping to reduce operational costs.